Mechanically operated input devices are opened and closed by the physical contact between a moving part in an industrial process, sometimes called a trip dog and is actuator of device.

Limit switches are mechanical devices that are activated by physical contact with moving object. The limit switch is composed of three basic components- a body, an operator and an actuator. They are used for such things, in industrial setting, as setting travel limits for machine parts, starting and stopping production sequences, detecting moving objects, monitoring an objects position, and numerous safety conditions. (For example in Hvac controls, you have a low limit and a high limit, both a triggered by lows and highs in pressure)

Body of Limit Switch- Every Limit Switch has a nameplate, which indicates the switch's contact configuration, standards and testing organizations for the switch is in compliance with. Your'll see SPDT (Single Pole Double Throw) or DPDT (double pole double throw) or etc at the contact configuration part. The NO contact is across one set of terminals and the NC is across another set of terminals. The NC usually has double break contacts.

The Operator Head seem to be of two types - the plunger type and the roller lever type/

Limit Switches rely on external pressure or movement against the actuator to open or close the contacts inside the body.

When installing a limit switch, there are two essential things to keep in mind. The limit switches range of motion must not be infringed upon and must meet the manufacturers requirements. Second, the correct mounting and placement is critical for performance.

(image source =http://www.standardelectricsupply.com/productimages/PIC_09008926808b5e2b.jpg)

Trip Dogs- The cams designed to move limit switch operation is called trip dogs. The rip dogs unique shape provided proper limit switch lever rotation and plunger//rod depression.

(image source =http://www.annpurnaelectricals.com/images/jaibalaji/Limit-Switch-Series.jpg)

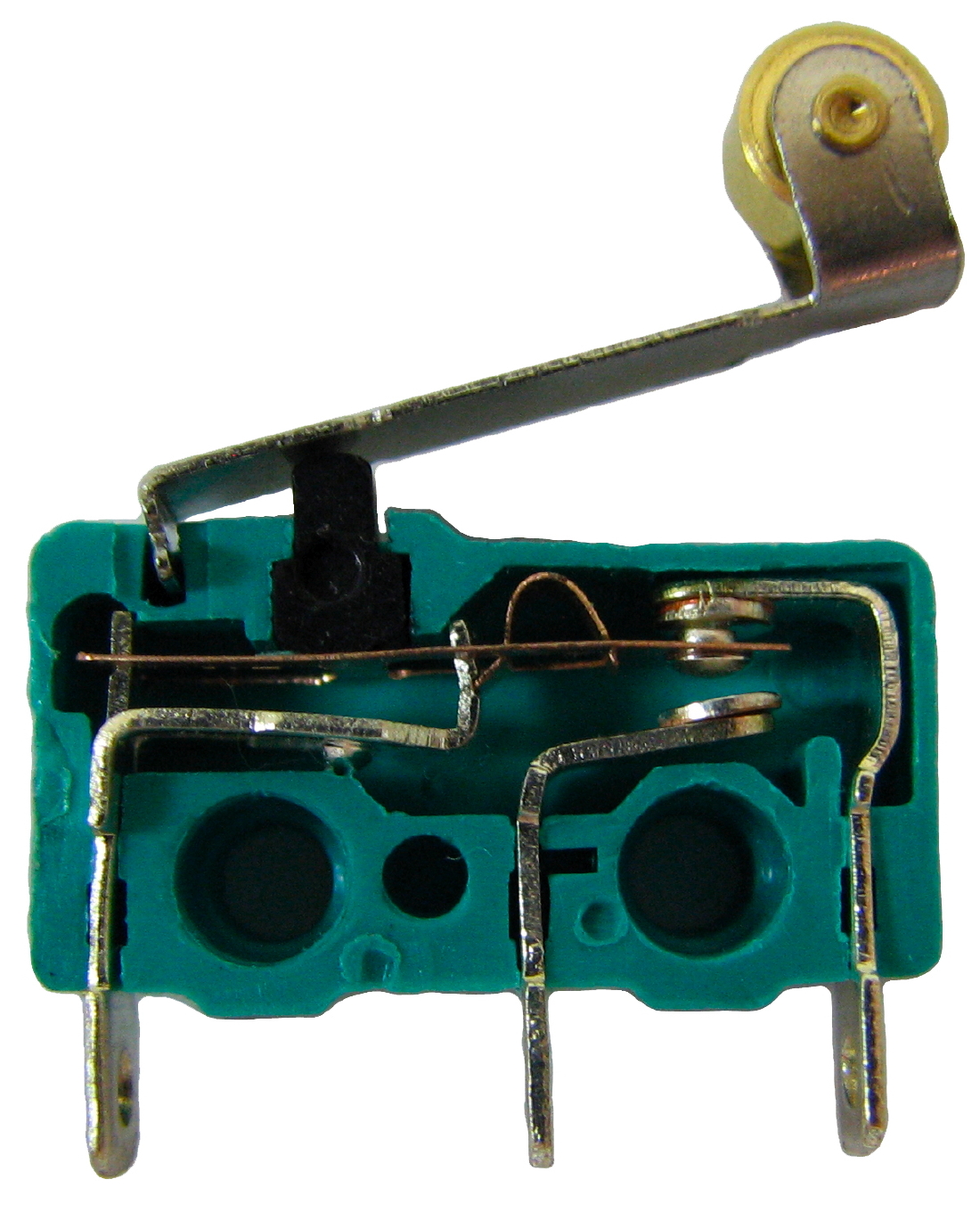

Miniature Switches or Micro Switches are a subclass of limit switches that have similar physical and electrical characteristics. Theses switches are sometimes mounted in larger switches to cause the switching action.

(image source=https://upload.wikimedia.org/wikipedia/commons/f/f8/Microswitch.jpg)

Miniature switches have fast switching action and are often called fast action switches. Miniature swiches are often used in equipment enclosures to detect open panel doors, missing equipment guards or things like that.

3-2 Automatically Operated Input Devices

Automatically Operated Input Devices - are triggered by a change in a process parameter. Process parameters include liquid level, pressure, fluid flow and material temperature. In general, these devices are either discrete or analog type. The set points for the discrete type are specific process parameter values. The analog type produces a continuously changing electrical output that is proportional to the parameter measurement.

Flow Switches- automatically or process actuated flow switches detect a change in a pipe's liquid flor or a duct's gas flow. Flow switches are used in such things as boilers, cooling lines air compressors and fluid pumps.

(image source = http://www.lamons.com/public/images/products/flow-switch.jpg)

Level Switches/ float switches- are discrete switches used for the control of a liquid or granular material levels in tanks.

Pressure switches- change state of contact based on pressure applied to the device by air, water = or another fluid. There are three main categories of pressure devices: Positive pressure, vacuum (negative pressure) and differential pressure. Most of these devices work on two principles.

1) a gas is compressible so a gas at a higher pressure occupies less volume than the same gas at a lower pressure.

2) Principle two states that liquids are not compressible and therefore transfer pressure that are applied on them.

Positive switches are actuated when additional pressure is added to the system.

Vacuum switches function when gas or air is removed from the system/

Differential pressure switches, measures the difference of pressure from two pressure sources

Pressure switches use different sensing devices to detect pressure. Most common sensing devices are diaphragm, bellows and piston.

Diaphragm used for low pressure applications

bellows for medium

piston for high pressure applications.

(image source= http://www.sensorsmag.com/files/sensor/nodes/2003/969/fig4.gif)

Deadband/ Neutral zone- is an area within a signal range where no action occurs (the system is dead)

Deadband prevents hunting. Hunting is the repeated oscillation or repeated activation -deactivation cycles. Hunting happens when small parameter changes make device turn on and off.

Temperature Switches- use a temperature sensing device to ecumenically change electrical contacts. They are used in fire alarm systems Hvac and several process control systems. 3 frequently used mechanical sensing devices are bimetallic strip, capillary tube and direct immersion probe (sexy)

(image source = http://www.electronics-tutorials.ws/io/io39.gif?81223b_

(image source= http://www.industrialcontrolsonline.com/sites/default/files/infotech/Infotec41/image010.gif)

(image source= http://www.dwyer-inst.com/images/addtl/TE_D_600x600.gif)

3-3 Troubleshooting

It's important, but I don't know of a good way to cohesively sum it up. Maybe I'll talk more on this next time.

No comments:

Post a Comment